Electro Sinter Forging (ESF) is a powder metallurgical method to rapidly produce a wide range of materials and components. Loose binder-less powders are inserted in the automatic dosing system or manually inserted in the mold. The automatic procedure applies a pre-pressure onto the powders to guarantee electrical contact hence it superimposes an intense electromagnetic pulse with a mechanical pulse. The two pulses last 30 to 100 ms and, after a brief holding time, the sintered component is extracted by the lower plunger and pushed out by the extractor to leave room for the next sintering.

By properly choosing the processing parameters either fully dense (>99% of theoretical density) or porous materials (down to 40% of theoretical density) can be obtained with consistent properties. The electro sinter forged objects have tight dimensional tolerances of ±0.02 mm in the pressing direction and as small as ±0.01 mm in direction perpendicular to the pressing action.

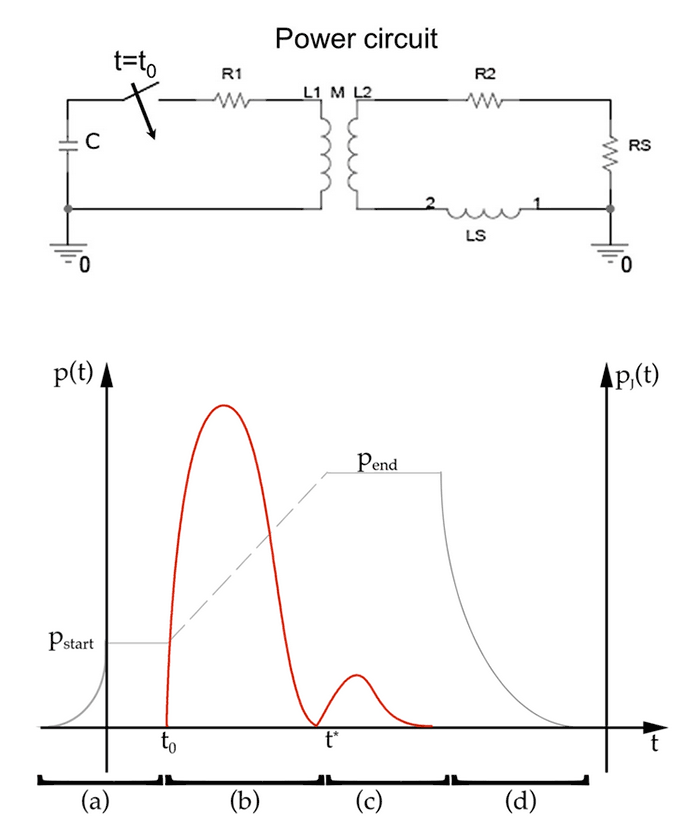

One realization of our sintering process is given by a capacitor discharge apparatus combined with a high speed press. The electrical power circuit is constituted by two mutually induction coupled power circuit:

- a) the primary where the capacitors and the solid state switch are positioned;

- b) the secondary where there is the sintering mould and plungers.

On standard machines the secondary circuit can reach a maximum voltage

- (a) pre-pressing

- (b) superposition of mechanical and electromagnetic discharge

- (c) hold in pressure

- (d) release

Built to work in complete autonomy, ESF machines are intrinsically safe, with little maintenance and low complexity:

- Maximum voltage on the secondary circuit < 60 V

- Each sintering pulse lasts less than 200 ms over the entire machine cycle thus possible exposition to electro-magnetic fields is extremely limited in time,

- No inert atmosphere or vacuum necessary, even for highly reactive materials (such as titanium and rare earths),

- Components are extracted and pushed away from the sintering mold at very low temperatures <100°C (<212°F),

- No binders are used in the powder so they do not require de-binding/evacuation.