Ancient as metallurgy itself, extremely resistant to corrosion and with a wide variety of industrial applications precious metals have accompanied mankind through its progress and evolution.

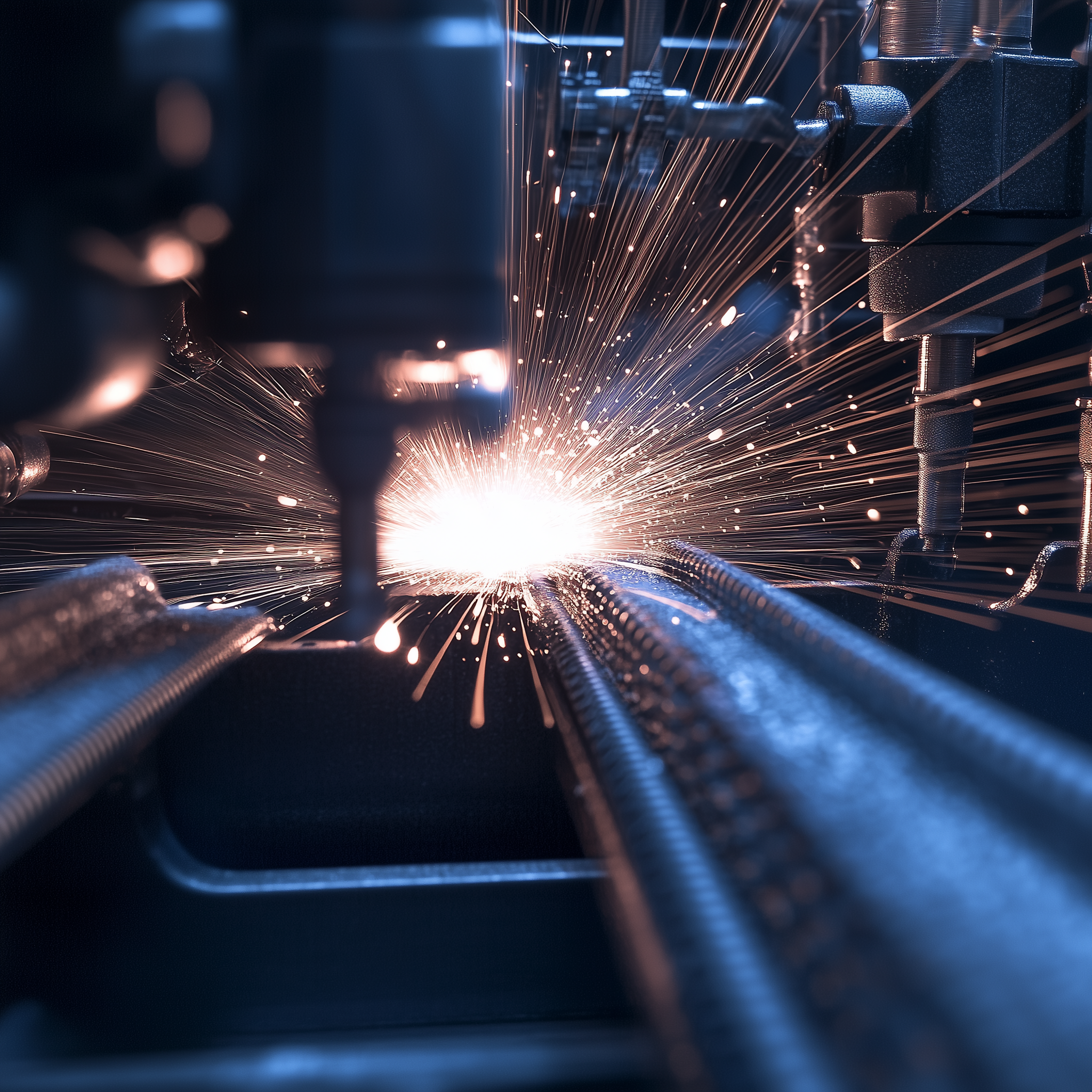

Due to the possibility to manufacture very fine grained and nano-crystalline alloys of high purity metals and alloys, EPoS’ technology, can drastically improve the scratch proof ability and hardness of precious alloys, without additional surface treatments or with a reduction in alloying elements, making precious alloys even more precious.

- Watch Bezels

- Balance wheels

- Watch Gears

- Blanks for jewelry and watchmaking

- Rings

- Electrical contacts/switches

- Composites for thermal management

- Special tools/electrodes

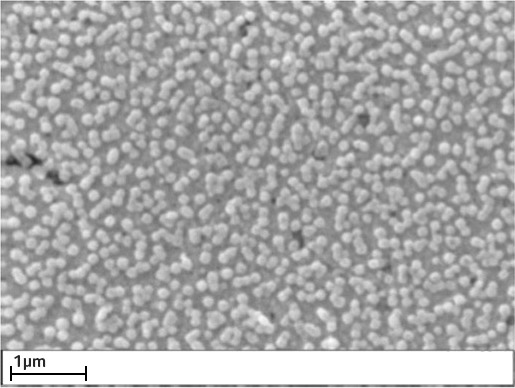

Hardnesses of over 280 HV have been obtained in 18K3N gold, high resolution SEM images on the left of sub-micron precipitates in nano-crystalline gold sintered by EPoS without heat treatment or addition of alloying elements.